Condensing Heating Only Boiler

Energy Efficiency Grade 1 to save your gas costs

- Highly efficient and durable storage type premium boiler, equipped with primary/secondary heat-integrated oval type fire tube, has been exported to North America.

- High Quality aluminum firetube have been adopted for Anti-corrosion and 1st grade efficiency. Main body is covered by Stainless(STS316L) for long durability

- A ceramic low-NOx premix burner and air/gas ratio control valve have been adoptedto control gas volume according to air volume and thereby achieve low noise andburn stably even when the flue is up to 10M long and bent up to 5 times (acquiredSouth Coast Air Quality Management District (SCAQMD) certification.)

- By adopting exhaust gas back draft damper to prevent external air inhaled when not in use, headwind prevention function and freeze-protection functionare built in.

- Storage type heat exchanger structure has half of less pressure drop thanthat of tankless type structure and circulates more quantity of heat to heat upyour room fast.

Boiler with utmost safety

- A gas leak detector is provided to avoid explosion or poisoning due to gas leakage.

- A seismic detector is provided to stop boiler operation when detecting a 4~5-magnitutde earthquake or vibration.

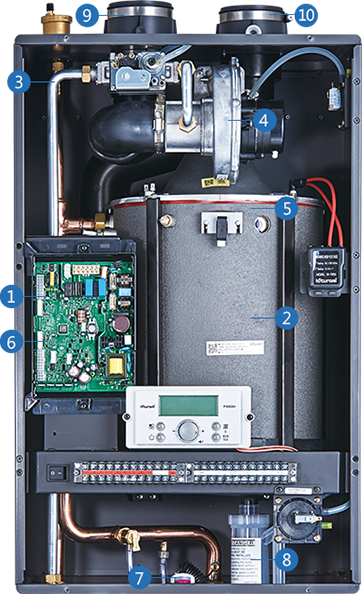

Internal Structure

-

1) Kiturami's exclusive built-in gas leak detector

The safest device to stop boiler operation and warn of gas leakage when gas is exploded or wastegas (burned gas) is leaked

-

2) Hot-water storage condensing heat exchanger

Primary heat/secondary heat-integrated typecondensing heat exchanger made of advancedcorrosion-resistant stainless

-

3) Air/Gas Ratio Control Valve

-

4) Premix fan

-

5) Eco-friendly burner

-

6) Controller

-

7) pressure gauge

-

8) Condensate water trap

-

9) Air inlet pipe

-

10) Air exhaust pipe

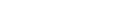

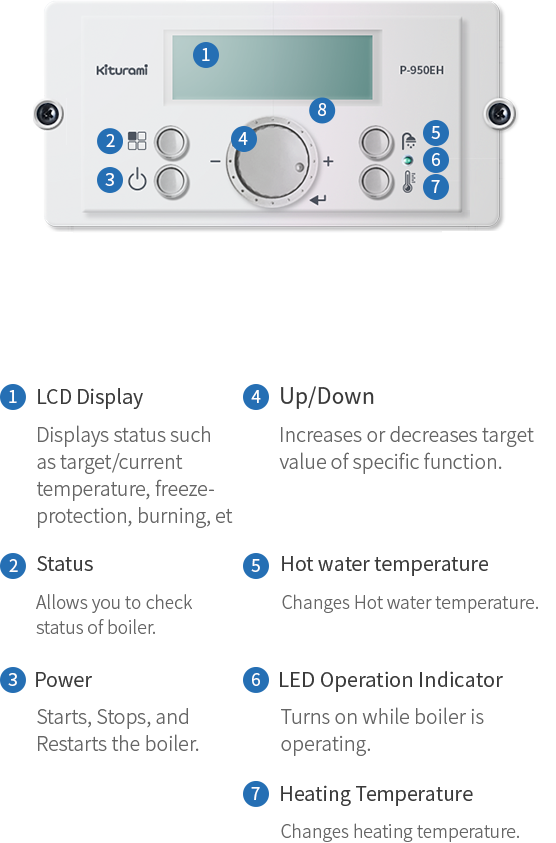

Convenient, easy-to-use controller with various functions(P-950H)

You can use various functions including leave, bath, schedule, etc. through very intuitive room controller.

Features and Benefits of Cascade System

Energy saving hot-water heating system to install and integrate multiple water heaters and boilers with smallcapacity instead of one hot-water heating boiler in large capacity, control hot water supply or heating room withone integrated temperature controller, and provide hot water or heating just as much as required

Standard cascade system piping diagram for K1 Condensing Gas Water Heater (ex)

-

Extensible capacity as much as required and savingmaintenance and management expenses

In existing medium-large boiler and water heater system,you should the whole medium-large boiler and water heatereven if you want just a little bit of heating and/or hot water.However, since cascade system lets you design capacityorganization when installing, you can operate the boiler orwater heater up to the required capacity. It helps you saveenergy expenses and management expenses such asmaintenance and troubleshooting.

-

Easy to install and move

If you install a medium-large boiler, you should bear excessivetransportation charge and wastefulness expenses and needwide space. If you install Kiturami cascade system withmultiple compact wall-mount type boilers, you can make thebest use of space without special space limitations.

-

Even if a boiler is broken, use the rest.

In the cascade system, multiple products are connected inparallel. If a product is broken, you can use the systemcontinuously because the rest will work normally.

-

Easy to control

The cascade central control system lets you manipulate theproduct easily and conveniently through the computer screen.Because one temperature controller is enough to control thesystem, you don't need to ask for help from a qualified boilertechnician.

Features, Benefits, and Effects of Cascade System

-

Storage type condensing ASME H heat exchanger

Corrosion-proof and durable stainless (ASTM-316L) heatexchanger equipped with heat/secondary heat-integratedoval type fire tube and exported to North America

※ ASME H certified heat exchanger: achieved quality and system certificationby product according to ASME CODE SECTION Ⅳ of American Society ofMechanical Engineers (ASME) which was made to ensure safety for boilerand pressure vessel used in whole industries. -

Kiturami downward combustion type eco-friendly burner

Eco-friendly technology which emits log- NOx and CO andspecial ceramic mat to prevent transformation or crack

Kiturami's exclusive built-in gas leak detector

The safest device to stop boiler operation and warn of gas leakagewhen gas is exploded or waste gas (burned gas) is leaked

-

Multi purpose damper with multiple functions of heatquantity control (TDR 10:1), headwind prevention,and freeze-protection is used.

By adopting exhaust gas back draft damper to prevent externalair inhaled when not in use, headwind prevention function andfreeze-protection function are built in (got approval to installcomplex exhaust pipe from Korea Gas Safety Corporation).Because the storage type heat exchanger (13L) has moreirrigation capacity than that of a tankless heat exchanger(approximately 1L), you don't need to worry about overheatingor boiling.

-

Quick heating by adopting storage type structure

Storage type heat exchanger structure has half of less pressuredrop than that of tankless type structure and circulates morequantity of heat to heat up the room with much load ofirrigation quickly.

-

Energy saving

• High-efficiency operation through the use of condensation technology

• Partial operation via control systemEnhanced maintenance

• Easy to install and efficient to maintain

• Easy to add boiler if hot water supply or heating load is increasedReduced initial cost

• Cheaper equipment price if considering heat quantity

• Easy to move and install in narrower place thanks to small sizeEnhanced boiler capacity options and hygiene

• Growing boiler capacity efficiently

• Quick hot water supply to prevent water pollutionConvenient construct ability

• Integrated modular type to reduce construction period

• Improved construct ability by small equipment and PVC flueComfort and convenience

• Comfort living environment according to quiet operation

• Easy to use by using front controller and cabled\ remote control

| Unit | Model | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Items | 48DB | ||||||||

| Central Heating Circuit | ㅡ | Closed type | |||||||

| Installation / Flue(Exhaust & Intake) type | Type | Wall hung, FF, FE | |||||||

| Fuel type | GAS | LNG,13A | LPG | ||||||

| Heating output | Gross | Condensing | kW | 52.7 | |||||

| ㎉/h | 45,000 | ||||||||

| Conventional | kW | 55.8 | |||||||

| ㎉/h | 48,000 | ||||||||

| Seasonal | kW | 17.4 | |||||||

| ㎉/h | 15,000 | ||||||||

| Efficiency | FF | Gross | %Total | 87.1 | 87.5 | ||||

| Seasonal | 95.9 | 95.4 | |||||||

| FE | Gross | 87.9 | 97.5 | ||||||

| Seasonal | 94.7 | 95.1 | |||||||

| Max. Gas consumption | kW | 59 | 60.40 | ||||||

| ㎉/h | 52,000 | 51,000 | |||||||

| Nominal inlet Gas pressure | kPa (mmH2O) |

town gas(LNG 13A) : 2.0 + 0.5, -1.0(200 + 50, -100) LPG : 2.8 ± 0.5 (280 ± 50) |

|||||||

| Max. operating pressure (Heating) | kPa (kgf/㎠) | 980(10) | |||||||

| Electric consumption | W | 70 | |||||||

| Outer case dimension | W X H X D | mm | 500 X 814 X 425 | ||||||

| Exhaust Max. Temp | ℃ | 105 | |||||||

| Multiple Exhaust(Max. Temp ) |

70 | ||||||||

| Weight | kg | 45 | |||||||

| Connections | Gas inlet connection | A | 15 (PT 1/2") | ||||||

| Central heating return and outlet | A | 25 | |||||||

| Flue connections | Φ | Intake 75, Exhaust 70 | |||||||

| Electric Supply | ㅡ | AC 220V X 60㎐ | |||||||

| Circulation pump | ㅡ | External pump | |||||||

- ※ Design and specification might be changed for improving quality without notice and the data is stated by KITURAMI R&D

(0개)

(0개)

(0개)

(0개)

본 웹사이트에 게시된 이메일 주소가 전자우편 수집 프로그램이나 그밖의 기술적 장치를 이용하여 무단 수집되는 것을 거부하며, 이를 위반시 정보통신망법에 의해 형사처벌됨을 유념하시기 바랍니다.

이메일을 기술적 장치를 이용하여 무단으로 수집, 판매, 유통하거나 이를 이용한자는 「정보통신망 이용촉진 및 정보보호」등에 관한 법률 제 50조의 2규정에 의하여 1천만원 이하의 벌금형에 처해집니다.

01. 누구든지 전자우편주소의 수집을 거부하는 의사가 명시된 인터넷 홈페이지에서 자동으로 전자우편주소를 수집하는 프로그램, 그 밖의 기술적 장치를 이용하여 전자우편주소를 수집하여서는 아니된다.

02. 누구든지 제1항의 규정을 위반하여 수집된 전자우편주소를 판매·유통 하여서는 아니된다.

03. 누구든지 제1항 및 제2항의 규정에 의하여 수집/판매 및 유동이 금지된 전자우편주소임을 알고 이를 정보전송에 이용하여서는 아니된다.